Our disassembly Department

All of our disassembly, machining, and processes are all completed in our Virginia Beach manufacturing plant.

After all, disassembly is complete, we then heat treat all components in our large block and head oven.

Various components are "Red Tagged" for scrap metal disposal. We have strict QC standards that start in the Disassembly department. We replace, rather than repair component parts that don't meet our standards.

heat treat and shot blast DEPARTMENT

Pictured above are various cylinder blocks and heads waiting for thermal heat treat and cleaning in one of our convection ovens.

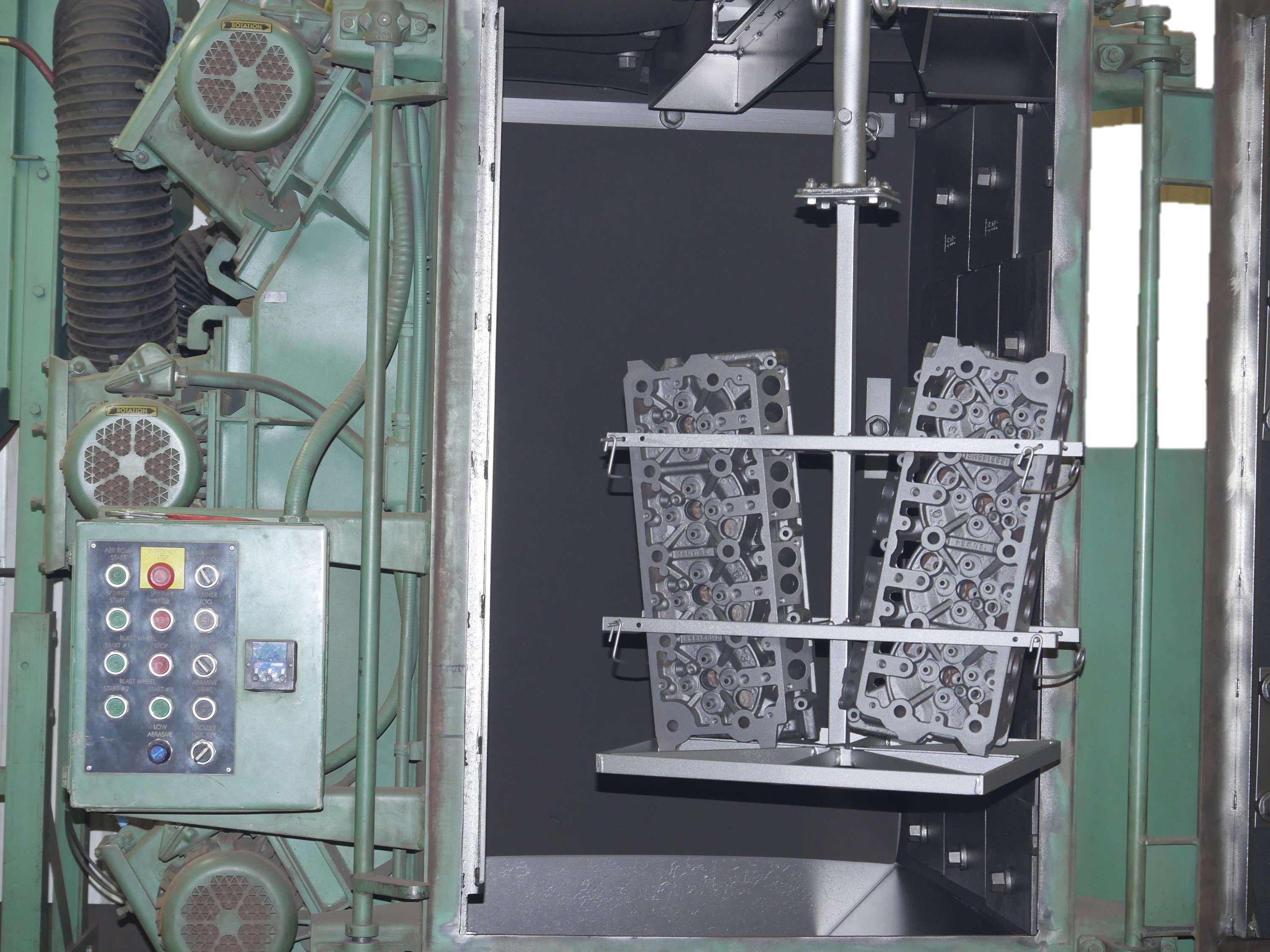

Once the heat treat process is complete we then shot blast various components in one of our many

Pictured above, cylinder blocks are being loaded into oven cages in preparation for thermal heat treating and cleaning.

Wash and rust inhibitor department

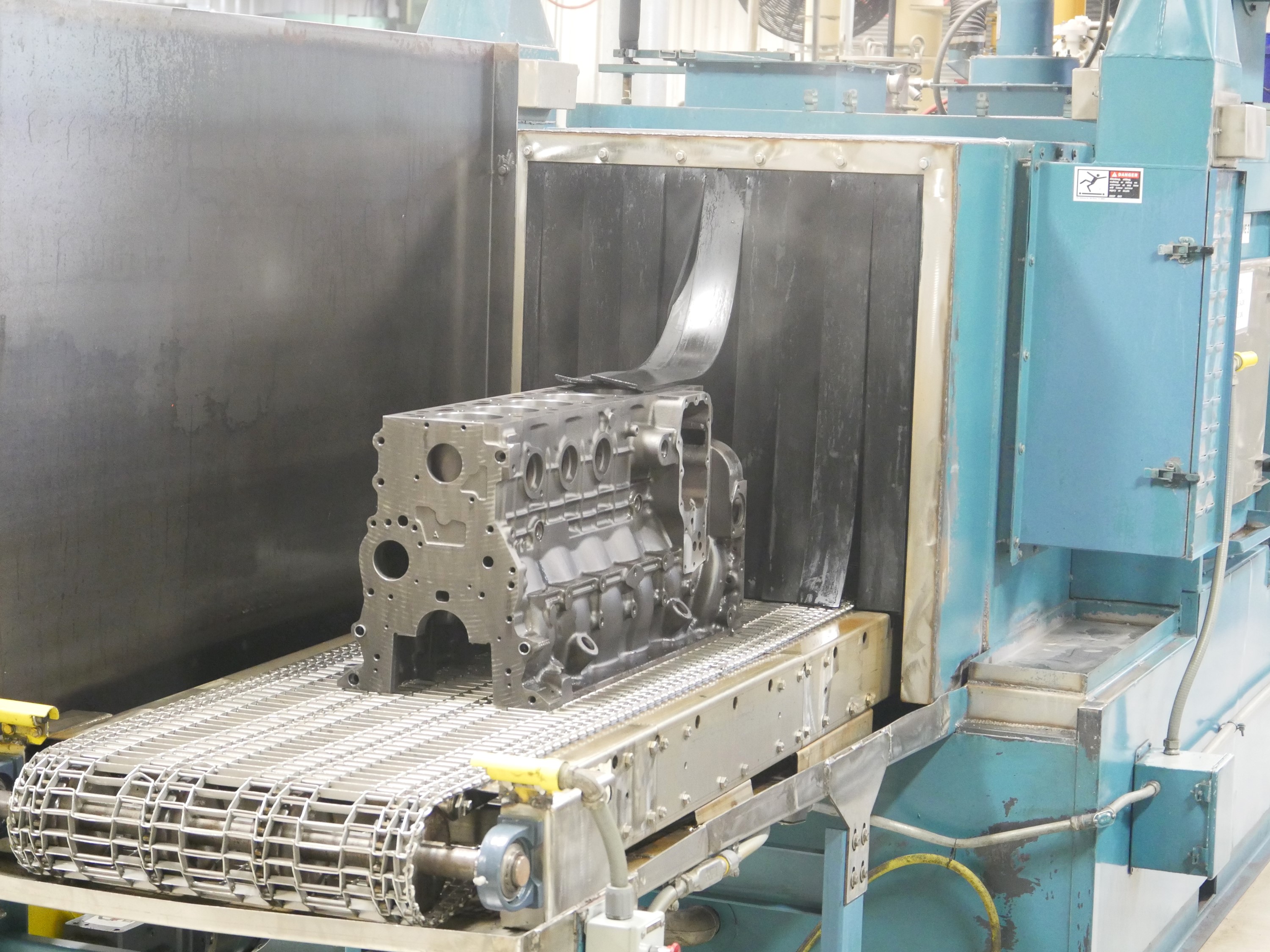

We have industrial, 45-foot-long pass through wash plants. Blackwater Engines utilizes aqueous-based parts washers, water-based cleaning agents, and rust inhibitors. These are used to ensure high levels of cleanliness and environmental preservation.

All components are thoroughly washed in our pass-through wash plant.

Pictured above is a crankshaft entering a pass-through washer for a 30-minute cleaning process.

Exiting the pass-through parts washer is a cylinder block after a rust inhibitor treatment is applied.

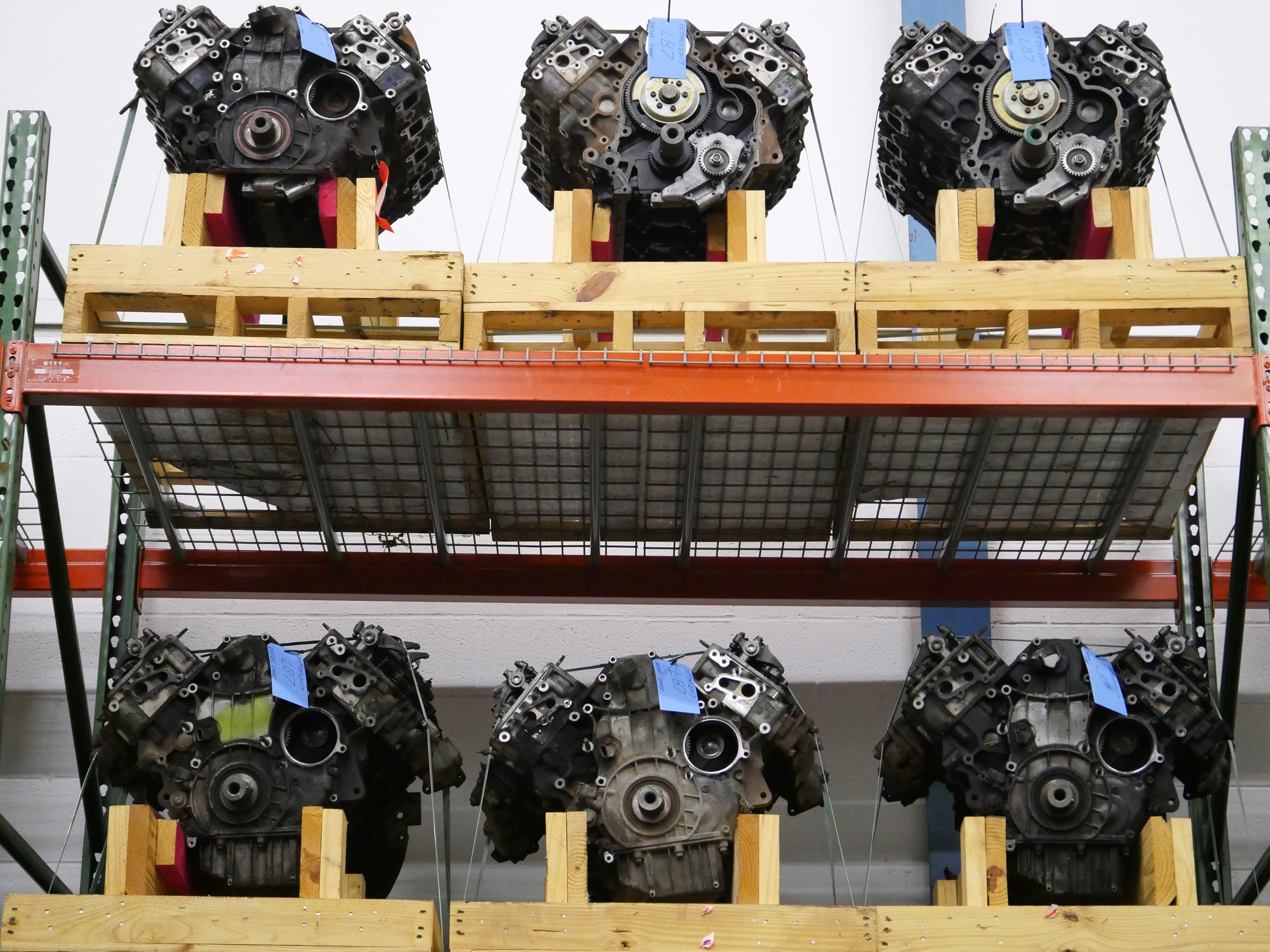

THE WAREHOUSE

Our warehouse contains our customer core returns, and our core product, sourced from core suppliers nationwide. Long block cores and core components are inventoried in preparation for disassembly.