Remanufactured Ford Engines

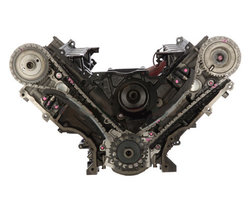

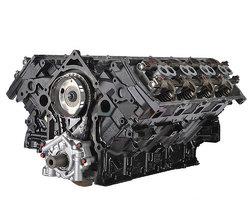

Blackwater Engines has vast experience in the industry. In our selection of remanufactured Ford engines, you will find the 4.6, 5.0, 5.4,7.3, 6.0, 6.4, and 6.7 as well as many other Ford engines.

When you choose a remanufactured Ford engine from our inventory, you are choosing dependability and strength for your vehicle. To retrieve the replacement engine you need, all you have to do is place an order, and we will get back to you shortly.

No matter the application, we want your engine replacement to be effortless, which is why we include an instruction manual with each purchase. But if you have any questions or concerns along the way, please do not hesitate to contact us.

-

3.5L LONG BLOCK

3.5L LONG BLOCK

-

3.8L LONG BLOCK

3.8L LONG BLOCK

-

4.2L LONG BLOCK

4.2L LONG BLOCK

-

4.6L LONG BLOCK

4.6L LONG BLOCK

-

5.0L LONG BLOCK

5.0L LONG BLOCK

-

5.4L 2V LONG BLOCK

5.4L 2V LONG BLOCK

-

5.4L 3V LONG BLOCK

5.4L 3V LONG BLOCK

-

5.8L LONG BLOCK

5.8L LONG BLOCK

-

6.8L LONG BLOCK

6.8L LONG BLOCK

-

7.5L LONG BLOCK

7.5L LONG BLOCK

-

3.7L LONG BLOCK

3.7L LONG BLOCK

-

3.8L LONG BLOCK

3.8L LONG BLOCK

-

6.0L LONG BLOCK

6.0L LONG BLOCK

-

5.3L LONG BLOCK

5.3L LONG BLOCK

-

5.7L LONG BLOCK

5.7L LONG BLOCK

-

7.4L LONG BLOCK

7.4L LONG BLOCK

-

5.0L LONG BLOCK

5.0L LONG BLOCK

-

7.0L LONG BLOCK

7.0L LONG BLOCK

-

5.2L LONG BLOCK

5.2L LONG BLOCK